I also learnt a lot of completely new terms and some work steps in flax processing that I didn't know from Westphalia.

"Boken"

Boken refers to softening the flax stalks before crushing with the aim of protecting the fibres during subsequent crushing because the crusher does not have to fall on the stalks with so much force. I was previously unaware of this work step.

"Knucke and Bolten"

The first hackle step here is a hackle with very widely spaced teeth (1.5 cm) to break off the upper tips of the plants. The waste served as padding material. It was important to finely break all the wooden parts of the flax. A crowbar with upright iron edges was used for this soft breaking.

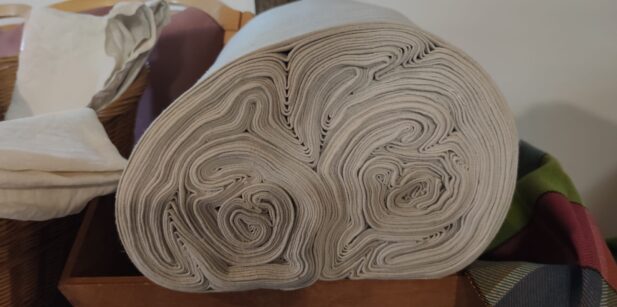

For the final fine hackling, hackling boards were used, with the iron nails standing tighter with each operation. The last short fibres were combed out and the long fibres were split open by hitting the hackle tips hard. A "Knucke" (flax plait) was tied from the processed bundles. The finished bales of linen were called "Bolten".